300kg 1 Axis Servo Positioner

Click here to learn more

| ITEM | SPECIFICATION |

|---|---|

| Controlled Axis | J1 |

| Motion Range | 740°(-370°~ +370°) 12.9 rad(-6.45 rad~ +6.45 rad) Continuous Turn available |

| Max. Speed | 160°/sec 2.79 Rad/sec |

| Max Load Capacity | 300kg |

| Allowable Load Momentum | 36 kgf.m 353 N.m |

| Allowable Load Inertia | 2,350 kgf.cm • s2 240 kg.m² |

| Drive Method | Electric servo drive AC servo motor |

| Weight of 3000kg 1-axis positioner | 85kg |

| Weight of follower unit | 40kg |

| Installation Environment | Ambient temperature .0.45.Ambient humidity. Normally 75%RH or less Short term(within 1 month) 95%RH or less (No dew nor frost allowed) Vibration.0.5G or less |

500kg 1 Axis Servo Positioner

Click here to learn more

| ITEM | SPECIFICATION |

|---|---|

| Controlled Axis | J1 |

| Motion Range | 740°(-370°~ +370°) 12.9 rad(-6.45 rad~ +6.45 rad) Continuous Turn available |

| Max. Speed | 160°/sec 2.79 Rad/sec |

| Max Load Capacity | 500kg |

| Allowable Load Moment | 36 kgf.m 353 N.m |

| Allowable Load Inertia | 2,350 kgf.cm.s² 240 kg.m² |

| Drive Method | Electric servo drive AC servo motor |

| Weight of 3000kg 1-axis positioner | 85kg |

| Weight of follower unit | 40kg |

| Installation Environment | Ambient temperature .0.45.Ambient humidity. Normally 75%RH or less Short term(within 1 month) 95%RH or less (No dew nor frost allowed) Vibration.0.5G or less |

1000kg Single Axis Servo Positioner

Click here to learn more

| ITEM | SPECIFICATION |

|---|---|

| Controlled Axis | J1 |

| Motion Range | 740°(-370°~ +370°) 12.9 rad(-6.45 rad~ +6.45 rad) Continuous Turn available |

| Max. Speed | 120°/sec 2.09 Rad/sec |

| Max Load Capacity | 1000kg |

| Allowable Load Momentum | 36 kgf.m 353 N.m |

| Allowable Rotation Moment | 160 kgf.m 1,568 N.m |

| Allowable Bending Moment | 2,100 kgf.m 20,580 N.m |

| Drive Method | Electro servo drive by AC servo motor |

| Weight | 280kg |

| Installation Environment | Ambient temperature 0.45Ambient humidity.Normally.75% RH or lessShort term(within 1 month) 95% RH or less(No dew nor Frost allowed)Vibration. 0.5G or less |

1500kg Single Axis Servo Positioner

Click here to learn more

| ITEM | SPECIFICATION |

|---|---|

| Controlled Axis | J1 |

| Motion Range | 740°(-370°~ +370°) 12.9 rad(-6.45 rad~ +6.45 rad) Continuous Turn available |

| Max. Speed | 120°/sec 2.09 Rad/sec |

| Max Load Capacity | 1500kg |

| Allowable Rotation Moment | 160 kgf.m 1,568 N.m |

| Allowable Bending Moment | 2,100 kgf.m 20,580 N.m |

| Drive Method | Electric servo drive AC servo motor |

| Weight | 280kg |

| Installation Environment | Ambient temperature .0.45.Ambient humidity. Normally 75%RH or less Short term(within 1 month) 95%RH or less (No dew nor frost allowed) Vibration.0.5G or less |

4000kg Single Axis Servo Positioner

Click here to learn more

Floor Mount Type

| ITEM | SPECIFICATION |

|---|---|

| Rotation Range | Unlimited |

| Motion Range | 110 deg/sec |

| Allowable Falling Moment | 3500 kgf-m |

| Load Capacity | 4000 kgf |

| Control | As aux.axis, controlled by robot controller |

| Diameter Of Through - hole | 80 mm |

Wall Mount Type

| ITEM | SPECIFICATION |

|---|---|

| Rotation Range | Unlimited |

| Motion Range | 110 deg/sec |

| Allowable Rotational Momet | 180 kgf-m |

| Allowable Falling Moment | 3500 kgf-m |

| Allowable Inertia | 8500 kgf-cm-sec² |

| Control | As aux. axis. controlled by robot controller |

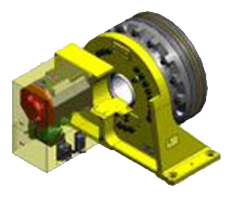

500kg 2 Axis Servo Positioner

Click here to learn more

• This is the 2-axis servo positioner for arc welding that has max.payload capacity in its class.

• 2-axis servo positioner has a 500kg payload capacity and the max. capacity of wrist moment and inertia in its class.

• Coordinated motion function integrated into FANUC ROBOWELD/ARC Mate series provides no error synchcronization motion. This greatly increase welding quality by constant relative speed and posture.

• Welding earth cable and plenty piping/wiring are integrated into hollow drive mechanism in the positioner. This can enable easy set up of the positioner.

• ROBOGUIDE is used to input CAD data and create programs offline. A welding program with multi-arm coordination motion is generated by tracing weld path on ROBOGUIDE.

• Created offline programs can be easily adjusted (callibrated) to the actual workpiece by Vision Sensor function.

• The positioner can be used safely by putting cover in arc-welding application.

• 2-axis servo positioner can be installed on the floor, upside down or inclined at any angle.

180 Indexing Turntable Systems (T Series)

Click here to learn more

• Payloads ranging from 250 Kg’s up to 5000 Kg’s.

• These tables have a unique table locking systems to maintain repeatability at the swing diameter of better than 0.05mm.

*We also manufacture a unique semi automatic turntable.

Heavy Duty Multi Position Turntables (THD Series)

Click here to learn more

These tables are designed to be used with loads up to 20 000 Kg’s, and output torques up to 60 000 NM using the correct drive package.

Many options are available including cam locking for zero backlash, shot pin locations, fixtures mounting frames and guarding packages.

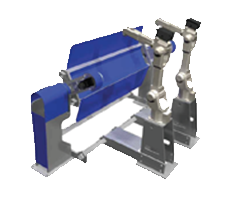

Head and Tail Stock Positioners (HT Series)

Click here to learn more

Ranging from 100kg’s to 20 000kg’s and with face plate centres up to 20 metres. Direct drive and slewing ring drive options are available.

Heavy Duty, Tilt and Turn (TT HD)

Click here to learn more

• Heavy duty, Tilt and Turn positioners ranging from 2000 Kg up to 20 000 Kg’s.

*Also available as a credit design.

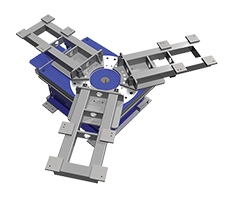

Centre Mount Positioners (CMT Series)

Click here to learn more

This positioner is one of the most flexible designs available and use a smaller cell foot print to other solutions. Its modular design allows for total flexibility.

With payloads from 250 Kg’s to 1000 Kg’s per side, face plate centres up to 4.5 metres and swing diameters up to 2.4 metres most products can be accommodated.

As the robot shares the swing arc as the table, the robot working envelope is utilized better than conventional systems.

It is possible to fit two robots in the centre or even fit a linear track to enable the robot to cover the whole work area.

With the robots mounted clear of the floor, the system is easier to programme and maintain.

Ferris Wheel Positioners (F Series)

Click here to learn more

Ideal for long thin components or when face plate distances greater than 3 metres are required. With all the axis driven it allows more flexible tooling design as full synchronous motion can be achieved.

Ferris wheel systems come with optional robot stands that clamp back to positioner for greater stability.

5 Axis Positioners (TX Series)

Click here to learn more

For greater flexibility each station has two axis drives.

Face plate centres are adjustable for sizes up to 3200 mm and with payloads up to 1000kg’s.

Hi Glyde Linear Tracks (HG Series)

Click here to learn more

Modular linear track systems in various payloads and accuracy grades for different applications including a cam lock option for zero positioning. All guides are protected and the track is covered with tread plate to prevent tripping hazards. Linear tracks can be mounted to the floor, wall or inverted.